Owen Sound-based company Hydrogen Optimized has signed a letter of intent with an unnamed large industrial company to supply more than 40 megawatts of its patented Rugged Cell water electrolyser capacity for hydrogen production.

Hydrogen Optimized President and CEO Andrew Stuart, says their parent company Key DH Technologies signed the confidential letter with the large industrial company.

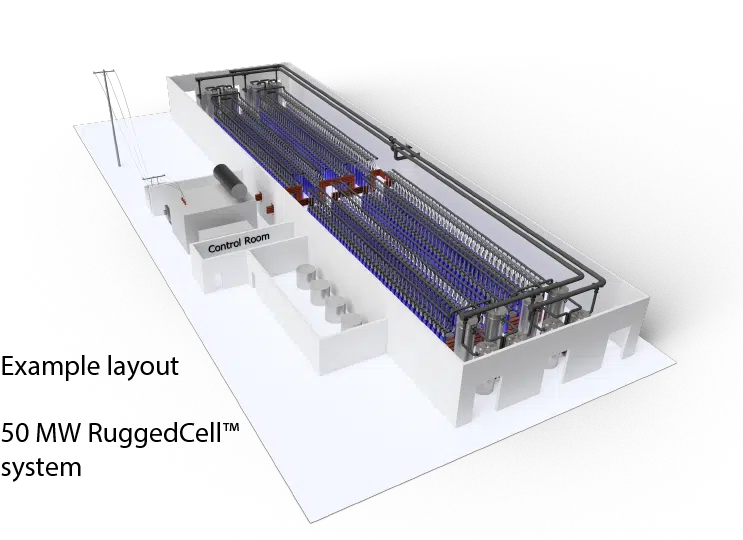

Stuart explains the RuggedCell water electrolyser system makes use of water flowing into the device and separates it into hydrogen and oxygen.

“The hydrogen can be used for many clean purposes such as chemicals, industrial processes and heavy-duty transportation fuel. What we do is do these on large scales so they are megawatt rated,” says Stuart.

Stuart says the RuggedCell is capable of taking large quantities of clean electricity, from sources like the wind or sun, and turn it into clean hydrogen, displacing the use of fossil fuels.

Stuart says the overall goal for the planet is to replace the use of oil and natural gas by 2050 to the necessary extent where we reach carbon neutral. A situation where we absorb as much carbon dioxide as we are emitting.

“What we are focused on is making the cleanest possible hydrogen production with almost no green house gas emissions, and that is what is going to help the world get to a carbon neutral position by 2050. But 20 per cent of the world’s oil, gas and coal is a very large number, it is equivalent to 25 million barrels of oil a day and so it is a very large number, perhaps thousands of gigawatts of renewable energy,” says Stuart.

Stuart says the RuggedCell system will be manufactured in Owen Sound and it will be sold globally next to sources of green electricity, and close by users of green hydrogen.

Stuart says the objective over the next four or five years, is to build their manufacturing base in Owen Sound to produce about 2,000 megawatts a year of the RuggedCell systems and sell a number to places in Ontario, but mostly exported to dozens of countries. They are also looking to over time establish joint venture manufacturing in countries like Australia and areas in Europe.

“More and more potential clients tell us they are looking for a water electrolysis system that can be economically deployed in the tens of megawatts and can be expanded at a relatively low incremental cost as the megawatt rating of the project grows,” says Stuart.