Owen Sound-based Hydrogen Optimized has signed a Momorandum of Understanding (MOU) with Green Hydrogen International (GHI) for the proposed development of a large electrolyzer manufacturing facility in Texas.

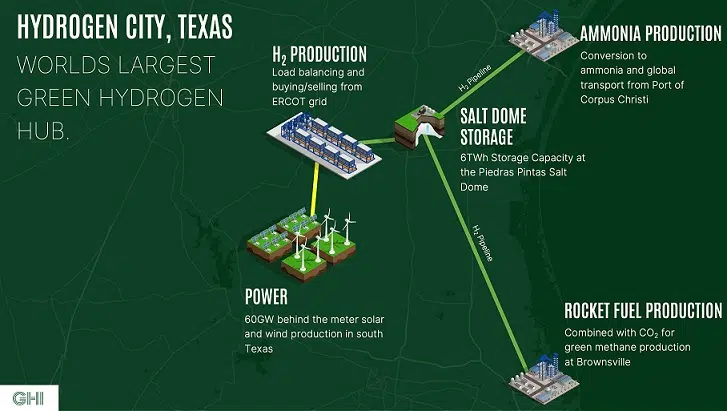

A release from Hydrogen Optimized says the factory would produce Hydrogen Optimized’s RuggedCell  water electrolyzers for GHI’s planned 60 GW “Hydrogen City” green hydrogen production and salt cavern storage hub to be built in South Texas.

water electrolyzers for GHI’s planned 60 GW “Hydrogen City” green hydrogen production and salt cavern storage hub to be built in South Texas.

GHI’s website describes Hydrogen City as the ‘world’s largest hydrogen storage hub.”

The production would be built out in steps, over several years.

Locations being considered for the factory include the Austin, Houston, Dallas, and Corpus Christi areas.

Hydrogen Optimized says in the meantime, it is, ‘highly focused’ on developing manufacturing capabilities and production at its Owen Sound facility. It says the technologies and expertise developed in Owen Sound will be applied in the proposed facility in Texas and other locations where there is demonstrated demand for RuggedCell  electrolyzers.

electrolyzers.

The ultimate target will be 5 GW a year of electrolyzer production.

The release says GHI intends to purchase the facility’s entire output for the first 10 years of operation to supply its Hydrogen City project.

Hydrogen Optimized says, GHI’s plan for gigawatt-scale green hydrogen production requires very large-scale water electrolysis technology.

Hydrogen Optimized says its patented high-current RuggedCell  technology was designed from first principles for large-scale hydrogen production at a significantly lower capital cost.

technology was designed from first principles for large-scale hydrogen production at a significantly lower capital cost.

The company is targeting individual RuggedCell  installations of 100 MW as a stepping-stone to systems up to 400 MW.

installations of 100 MW as a stepping-stone to systems up to 400 MW.

Hydrogen Optimized says, by comparison, most systems available in the market today cannot scale beyond 20 MW per unit

or in many cases, 5 MW per unit. It also notes, unlike its RuggedCell,  many systems use expensive iridium, which is not available at a volume required to meet multi-gigawatt annual global demand for electrolyzers.

many systems use expensive iridium, which is not available at a volume required to meet multi-gigawatt annual global demand for electrolyzers.

Hydrogen Optimized says that’s a key advantage to its RuggedCell  — because it has a dynamic response to variations in electrical current levels from zero to 100 per cent power loads in just a few seconds.

— because it has a dynamic response to variations in electrical current levels from zero to 100 per cent power loads in just a few seconds.

GHI Founder Brian Maxwell says in a statement, “The RuggedCell  design is the ideal solution for large-scale hydrogen projects like Hydrogen City,” adding, “Andrew Stuart and his team at Hydrogen Optimized have unmatched experience and technology expertise in green hydrogen production, and we’re proud to be working with them to develop the world’s largest green hydrogen production and storage hub in Texas.”

design is the ideal solution for large-scale hydrogen projects like Hydrogen City,” adding, “Andrew Stuart and his team at Hydrogen Optimized have unmatched experience and technology expertise in green hydrogen production, and we’re proud to be working with them to develop the world’s largest green hydrogen production and storage hub in Texas.”

Hydrogen Optimized notes in its release, that global electrolyzer capacity is expected to expand at a compound annual growth rate of 78 per cent, from 0.5 GW in 2022 to 84.7 GW in 2031, according to a March 2022 report from Guidehouse Insights.

The Owen Sound based company says this capacity is achievable realistically only through the widespread adoption of large-scale electrolysis technology.

Andrew T. B. Stuart, President and CEO of Hydrogen Optimized says in a statement, “We’re particularly excited to explore GHI’s plan to store green hydrogen in salt caverns, an approach that inherently recognizes the need to produce and store green hydrogen on a massive scale to unlock a region’s renewable energy potential and drive the transition to clean energy.”